Research

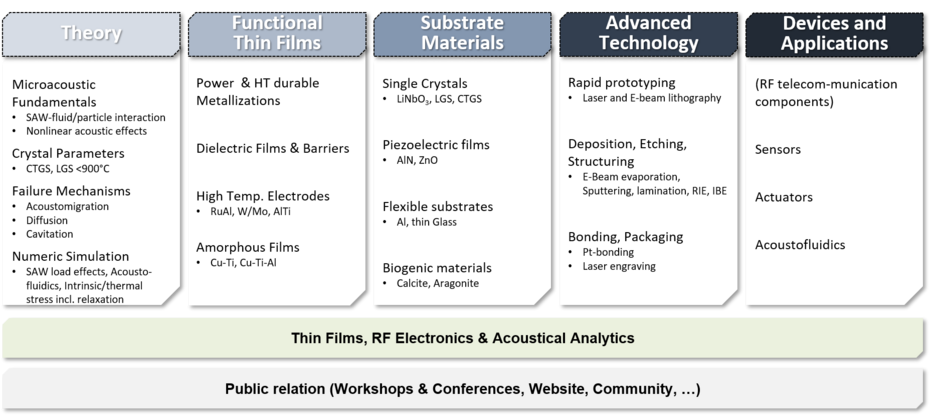

The members of SAWLab Saxony comprise scientists and technologists from IFW, different research institutions and industrial partners. Therewith our activities and competences span all topics related to acoustoelectronics: fundamentals, electrode and substrate materials, advanced thin film technologies and specific devices and acoustoelectronic applications.

The most important research and development topics cover:

Selected Results:

High-precision determination of acoustic material parameters of Cantangasite

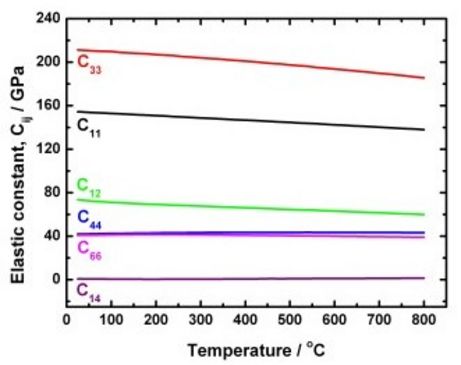

Catangasite (Ca3TaGa3Si2O14, CTGS) is a very promising substrate material enabling long-term stable operation of piezoelectric devices in high-temperature environment. We thoroughly investigate this ordered member of langasite family crystals for application in future SAW-based sensors. In addition to compatibility to advanced electrode metallisations, this comprises high-precision characterisation of CTGS with respect to all acoustically relevant material properties i.e. complete stiffness, dielectric and piezoelectric tensors, mass density, conductivity and attenuation. As a result, an excellent matching full set of high-precision acoustic material parameters was extracted for CTGS at room temperature. These data and the associated temperature coefficients also determined, covering the very wide temperature range from 4.2K to 1200K, provide a versatile basis for the accurate design of CTGS-based devices operating between cryogenic and high temperatures.

A. Sotnikov, B. Sorokin, N. Asafiev, D. Shcherbakov, G. Kvashnin, Y. Suhak, H. Fritze, M. Weihnacht, H. Schmidt, IEEE Trans. UFFC (2021), URL.

Y. Suhak, W.L. Johnson, A. Sotnikov, H. Schmidt, H. Fritze, MRS Advances 4, 515 (2019), URL.

Y. Suhak, M. Schulz, W. L. Johnson, A. Sotnikov, H. Schmidt, H. Fritze, Solid State Ionics 317, 221 (2018), URL.

Y. Suhak, M. Schulz, A. Sotnikov, H. Schmidt, S. Ganschow, S. Sakharov, and H. Fritze, Ferroelectrics 537, 255 (2018), URL.

M. Weihnacht, A. Sotnikov, Y. Suhak, H. Fritze, H. Schmidt, Proc. 2017 IEEE Intern. Ultrasonics Symp., 1-4 (2017), URL.

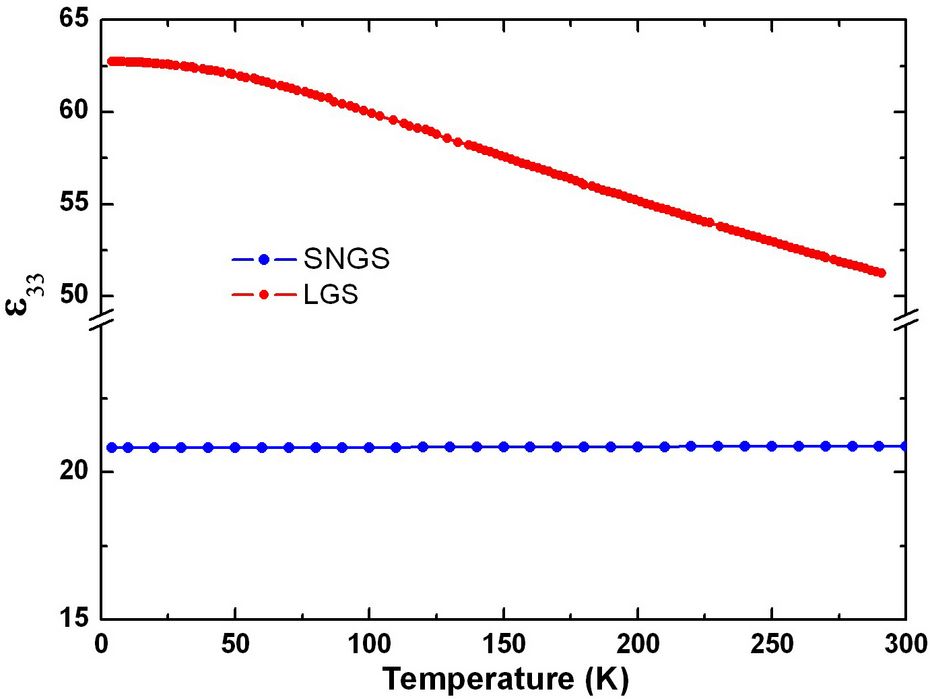

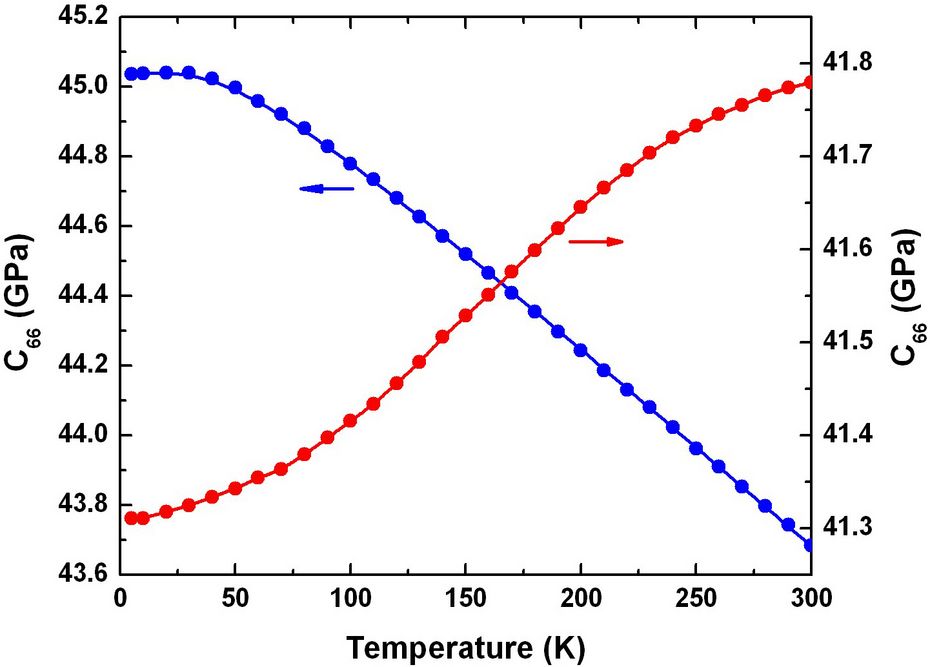

Elastic and dielectric properties of Langasite family crystals at low temperatures

Elastic and dielectric properties of La3Ga5SiO14 (LGS) and Sr3NbGa3Si2O14 (SNGS) piezoelectric crystals were studied at temperatures from 4.2 K to 300 K. The obtained results for the elastic constants (with the exception of C66 for LGS) are treated using Varshni approach based on the Einstein oscillator model. In LGS, the elastic constant C66 versus temperature shows a turnover point close to room temperature followed by a gradual decreasing with decreasing temperature down to 4.2K. It is also demonstrated, that high piezoelectric activity of the crystals keeps down to 4.2K which predestines clearly LGS and SNGS as promising materials for possible applications at cryogenic temperatures.

A.V. Sotnikov, E.P. Smirnova, H. Schmidt, M. Weihnacht, Phys. Solid State 57 (2015) 6, 1183-1187, URL.

A. Sotnikov, E. Smirnova, H. Schmidt, M.Weihnacht, J. Götze, S. Sakharov, Prodeedings of the 2015 Joint IEEE International Frequency Control Symposium and European Frequency and Time Forum, Denver, USA, 106-110 (2015), URL.

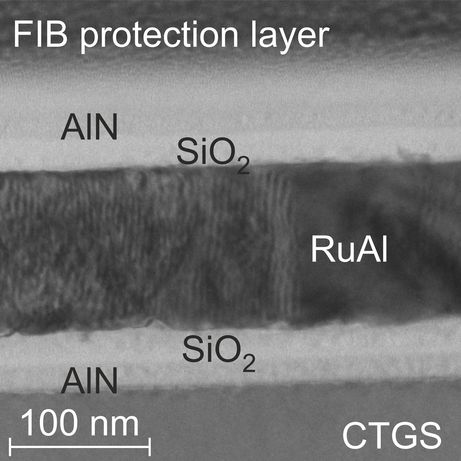

RuAl-metallization systems for SAW-driven wireless, self-sufficient sensors for usage at 600°C and beyond

The intermetallic RuAl alloy with its high melting point and a strong oxidation and corrosion resistance is a very promising alternative thin film electrode material for usage in high-temperature sensor devices. Our research results demonstrate that a high-temperature stability of RuAl-based films on the high-temperature-stable piezoelectric substrate Ca3TaGa3Si2O14 (CTGS) can be realized in combination with AlN and SiO2 cover and barrier layer. Thin films stable up to 800 °C in air and 900 °C in high vacuum for at least 10 h were realized at IFW Dresden. The barrier layers between the CTGS and the RuAl film are essential to prevent degradation since the substrate emits oxygen at high temperatures.

M. Seifert, G.K. Rane, S. Menzel, T. Gemming, Journal of Alloys and Compounds 684, 510-517 (2016), URL.

M. Seifert, G.K. Rane, S. Menzel, T. Gemming, Journal of Alloys and Compounds 688, 228-240 (2016), URL.

M. Seifert, G.K. Rane, S. Oswald, S.B. Menzel, T. Gemming, Materials 10(3), 277 (2017), URL.

M. Seifert, G.K. Rane, S.B. Menzel, S. Oswald, T. Gemming, Journal of Alloys and Compounds 776, 819-825 (2019), URL.

M. Seifert, Materials 13 (7), 1605 (2020), URL.

M. Seifert, E. Brachmann, G.K. Rane, S.B. Menzel, S. Oswald, T. Gemming, Journal of Alloys and Compounds 813, 152107 (2020), URL.

Next generation acoustofluidic aerosol generators, the underlying physics and future applications

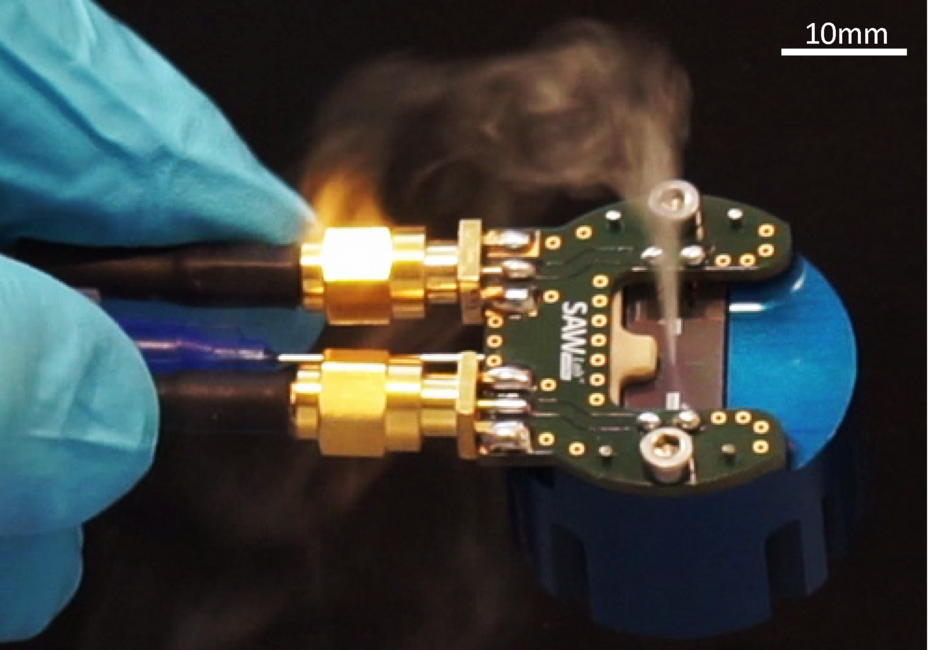

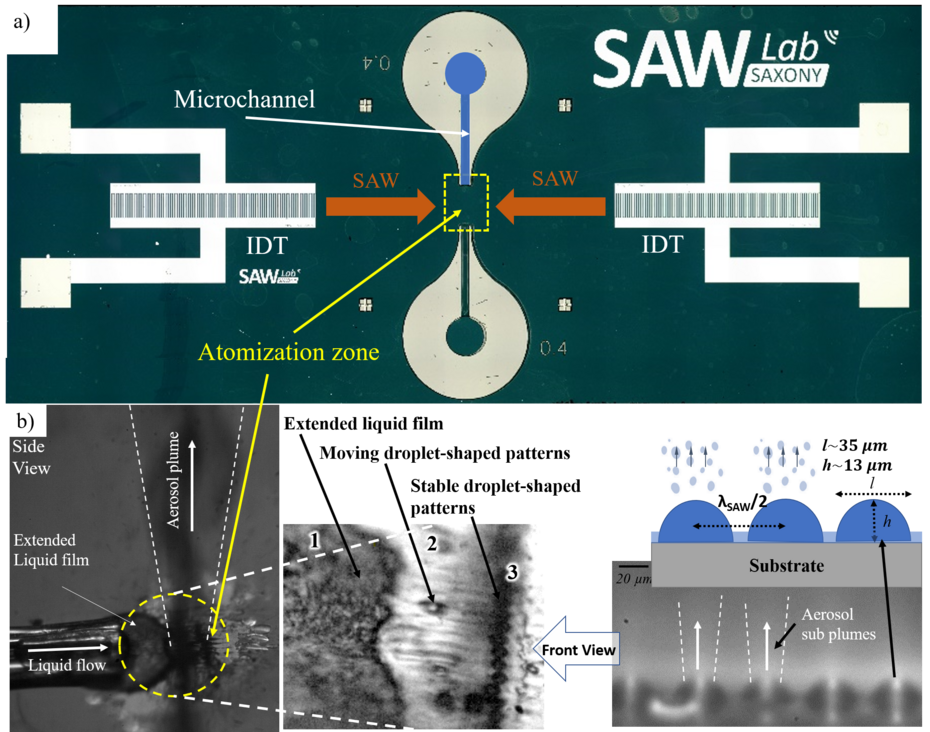

Compact SAW atomizers are capable to create directed fine mist aerosols with a narrow size distribution, as needed in many technical processes. We developed a compact SAW-based aerosol generator amenable to mass production fabricated using simple techniques including photolithography, computerized numerical control (CNC) milling and printed circuit board (PCB) manufacturing.

We are further investigating SAW-based aerosol generation mechanisms using e.g. high-speed videomicroscopy, rf-electrical measurements, laser-Doppler vibrometry and aerosol droplet analysis. Using this approach, we present comprehensive experimental results exploring the complexity of the acoustic atomization process, including the influence of fluid supply position and geometry, SAW power and fluid flow rate on the device functionality. These factors in turn influence the droplet size distribution, forming the basis for applications including liquid chromatography, pulmonary therapies, thin film deposition and olfactory displays. In recent studies, we operated our aerosol generator in the LACIS-T wind tunnel at different constant levels of air humidity to gain understanding in the underlying droplet formation mechanisms and to determine the initial droplet size distribution. The droplet source was identified as fluid micropattern, generated and stabilized in the atomization zone by the sSAW. Furthermore, we applied the technique to replace the fluid source in low-temperature plasma ionization mass-spectrometryfor improved compound selectivity.

Winkler, A.; Harazim, S. M.; Menzel, S. B.; Schmidt, H., Lab Chip 15, 3793-3799 (2015), URL.

Winkler, A.; Harazim, S. M.; Collins, D. J.; Brünig, R.; Schmidt, H.; Menzel, S. B., Biomed Microdev 19,1 (2017), URL.

M. Roudini, D. Niedermeier, F. Stratmann, and A. Winkler, Physical Review Applied 14:1 (2020), URL.

A. Kiontke, M. Roudini, S. Billig, A. Fakhfouri, A. Winkler, C. Birkemeyer, Scientific Reports 11, 2948 (2021), URL.

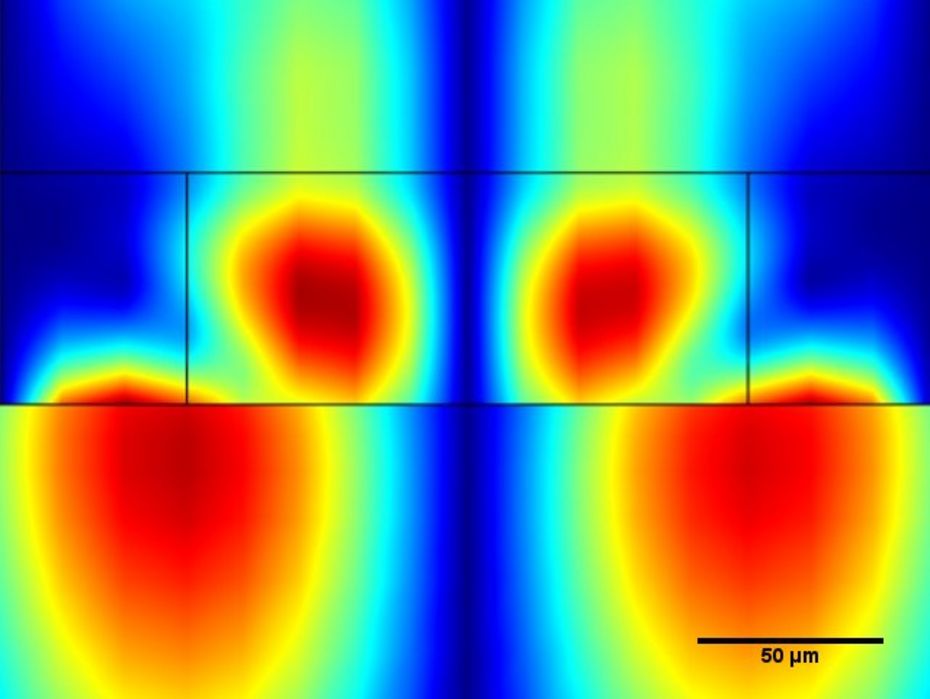

(bottom) SAW amplitude and acoustic pressure field in the microfluidic channel, based on a fully 3D-coupled FEM simulation

Acoustofluidic separation of blood components

Our newest generation of Surface Acoustic Wave (SAW) driven microfluidic devices can separate individual components from complex dispersions. Here, we demonstrate a platform for the enrichment of PLTs with a higher separation efficiency, substantially higher cell throughput and lower applied power requirements compared to conventional systems. The proposed device is produced through lithographically defined, on-chip SU‑8 microchannels enclosed by a PDMS cover, making the technology mass producible and enabling easy integration onto current Lab-on-a-Chip systems. Based on FEM simulations, electric and acoustic measurements, we also demonstrate, for the first time, a comprehensive analysis of SU-8 based acoustofluidics.

C. Richard, A. Fakhfouri, M. Colditz, F. Striggow, R. Kronstein-Wiedemann, T. Tonn, M. Medina-Sánchez, T. Gemming and A. Winkler, Lab-on-a-Chip, Advance Article, DOI: 10.1039/C9LC00804G (2019) URL

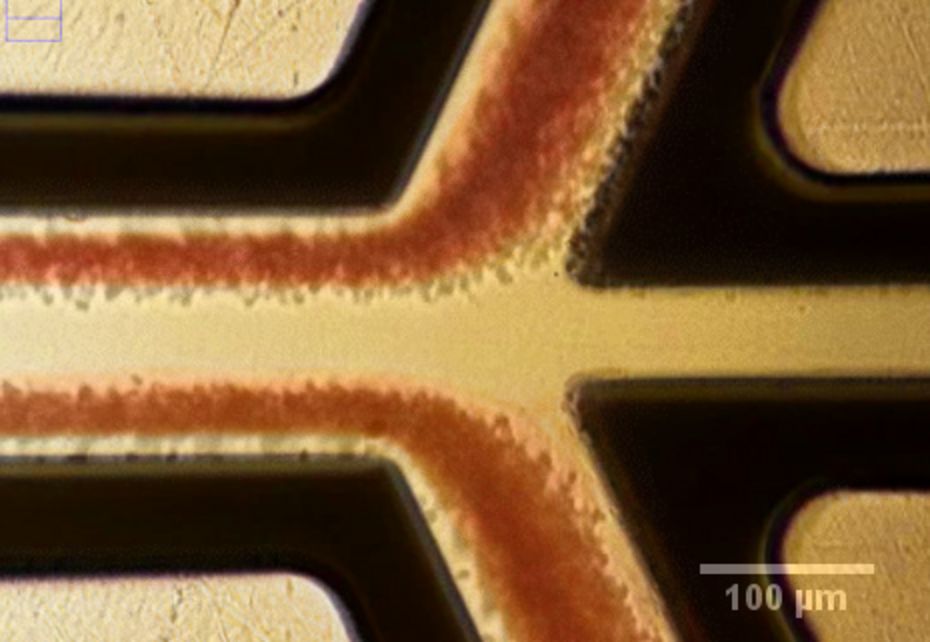

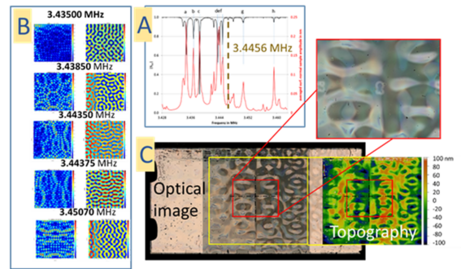

Directed property variation of RF sputtering grown thin films on standing acoustic wave substrates

Applying rf-acoustic stimulation to a substrate during the deposition of thin films can lead to locally altered and even patterned film growth and film properties, respectively. In collaboration with CSIC (Spain), we demonstrates for the first time the possibility of tailoring the microstructure and lateral thickness distribution of TiO2 thin films via oblique angle magnetron sputtering deposition onto in-situ acoustically actuated substrates. Comparative studies with evaporated TiO2 films, the use of distinct AW wavelengths and the analysis of thin films prepared in a normal configuration reveal that film property differences result from an interplay between substrate surface polarization and plasma sheath effects during MS deposition.

A. García-Valenzuela, A. Fakhfouri, M. Oliva-Ramírez, V. Rico-Gavira, T. Cristina Rojas, R. Alvarez, S.B. Menzel, A. Palmero, A. Winkler, A.R. González-Elipea, Materials Horizons 8, 515-524 (2020), URL.